Features of Aluminum Profile For Solar Panel

| Alloy | Standard | Surface Treatment | Further Process | Certificate |

| 6005 T5/T6, 6060 T5/T6, 6061 T4/T6, 6063 T5/T6, 6463 T5/T6, 6082 T5/T6, etc. | GB 5237-2008, JISH, AAMA, GB, BS, En | Mill finish, Powder Coating, Anodizing, Wooden grain, Electrophoresis, PVDF Painting, Sanding blasting, Polishing, etc. | Drilling, Bending, Welding, Precise cutting, Punching, Fabrication of finished products, etc. | CE, DNV, TUV, ISO9001

|

Packing and Delivery of Aluminum Profile For Solar Panel

Packing of Aluminum Profile For Solar Panel:

A protective film will stuck on profile's visible surface, and a heat shrink film or craft paper will cover the outside. Customized packing of aluminum profile for solar panel is also available.

Delivery of Aluminum Profile For Solar Panel:

1. Die development of Aluminum Profile For Solar Panel: 15-25 days after payment is received and drawings are confirmed.

2. Production time of Aluminum Profile For Solar Panel: 25-30days after the deposit is received and samples are confirmed.

Aluminum VS Steel Profile For Solar Panel Frame

Traditionally, steel has been the metal of choice for large commercial projects, and for good reason.

Steel is abundant and easy to purchase. Steel is very suitable for static load bearings and has a high modulus of elasticity and excellent fatigue strength. The mechanical properties and forming properties of steel are well known, so the design of structural components (such as frames, trusses and I-beams) is relatively simple.

However, the use of steel also has obvious disadvantages. On the one hand, it is heavy and must be transported and installed in remote areas at high energy costs. Compared with steel profiles, aluminum profile panel is light and energy-saving.

Manufacturing longer steel profiles requires welding parts to join together, which increases manufacturing costs. Of course, steel is prone to corrosion, so the surface must be passivated, painted or powder coated-these are not permanent solutions for longevity.

Fortunately, the use of aluminum profiles has many advantages that engineers and product developers may not be aware of. To take advantage of these advantages, engineers should first pay attention to the exact conditions under which the structure must be executed.

The Benefits of Aluminum Extrusion Profiles for Solar Energy

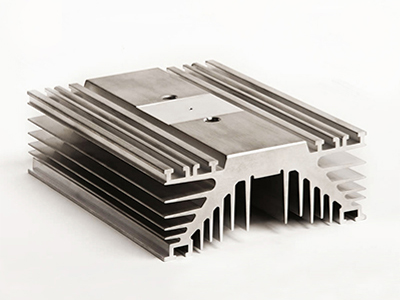

The innovation of aluminum extrusion technology provides higher stability for the solar panels on site. In order to maximize efficiency, solar panels need to be positioned with extremely high precision. Even if the position is slightly shifted, the output potential of the power supply can be reduced by several percentage points.

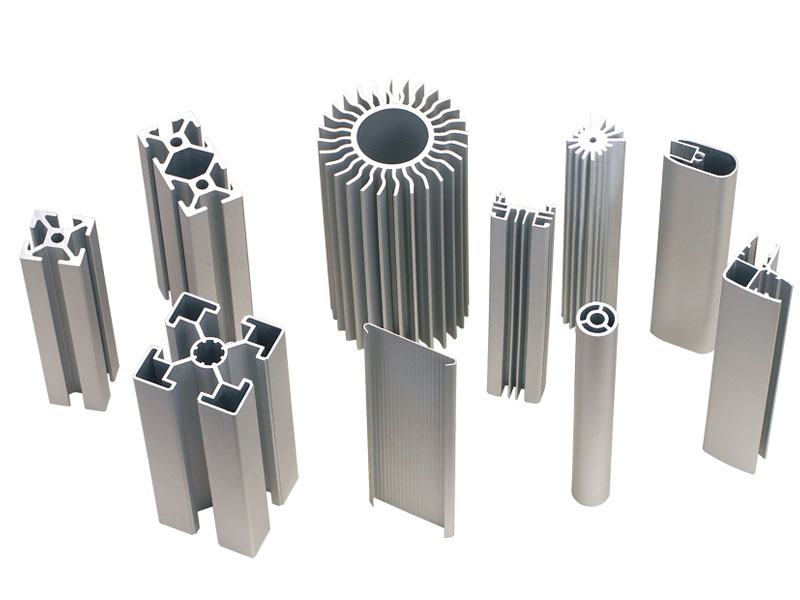

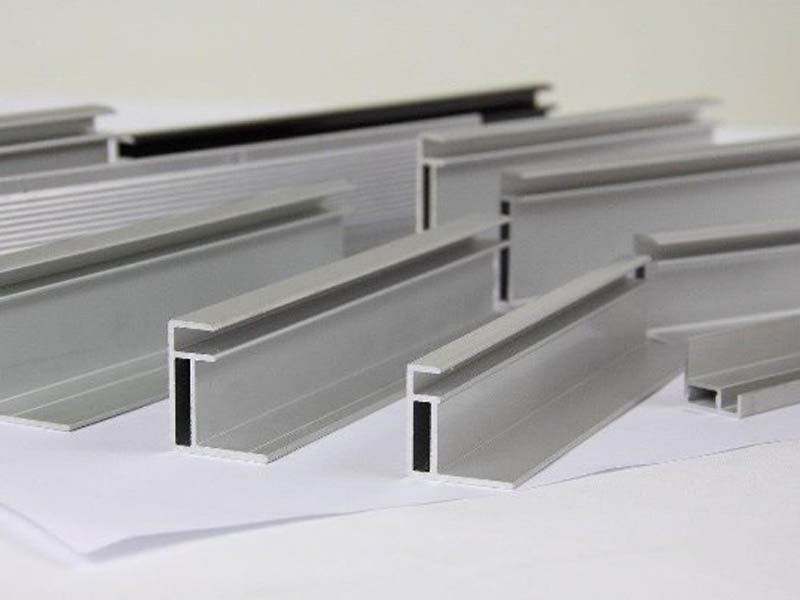

Aluminum extruded profiles can be used to create integrated frames (including frames, brackets and connectors) for solar panels in various situations. Compared with other metal options, aluminum products have many advantages:

Frames and supports made of aluminum extrusion are lighter than other metals, so Aluminum solar panel frame is easier to transport and assemble in remote areas where large solar power plants are common. This lightweight function can also be used for rooftop solar installations because the architectural specifications of these buildings have a limited capacity to support the additional weight of the panels and underlying structures.

Aluminum is corrosion resistant, which adds to the weather resistance advantages of these solar panel architectures.

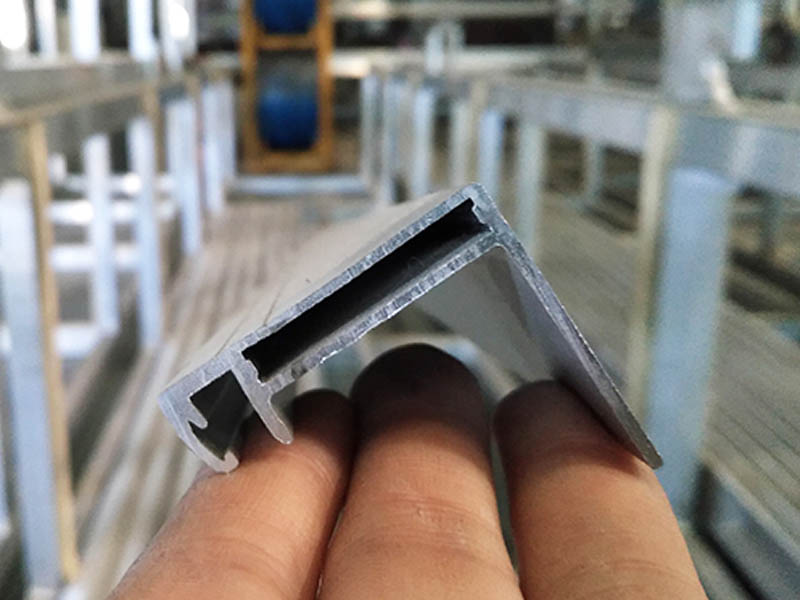

The malleability of aluminum allows flexible design of solar panel supports and frames. Extruded aluminum tubes can be connected at atypical and precise angles while requiring fewer parts and connections. This provides the necessary precision for the alignment of solar panels to achieve maximum energy output.

English

English 日本語

日本語 한국어

한국어 français

français Español

Español русский

русский português

português العربية

العربية tiếng việt

tiếng việt ไทย

ไทย slovenčina

slovenčina