Otalum offers an in-house anodizing facility and ensures that you get the high-performance anodized aluminum finishing exactly what you need.

Our 2-step aluminum anodizing process delivers an excellent finish that won't fade for decades. This 2-step anodising process includes mechanical and chemical processes. Mechanical finishes can be achieved by sanding, polishing, buffing, burnishing, or glass bead blasting. The chemical processes include etching, chemical polishing, anodizing and electrophoresis. As a professional aluminum surface finishing service supplier, Otalum will choose the most proper anodising aluminium process according to your specific requirement and produce the products with the ideal finishing.

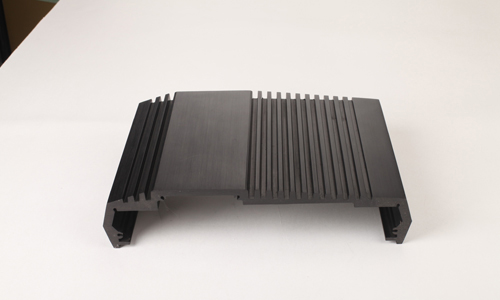

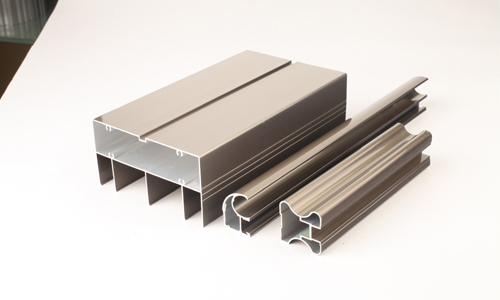

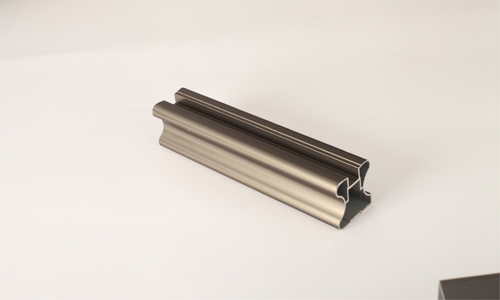

Normally, we offer the choices of clear aluminum anodizing, titanium anodising, brown anodizing and black hard aluminum anodizing. All of the aluminium anodizing processes are available in both clear and electrolytic colours. The thickness of the anodic layer is at least 10 microns and it can be thicker as you wish.

Anodizing is an electrochemical process that accelerates and thickens the original protective oxide layer. The resulting anodic coating is part of the metal but has a porous structure that allows secondary infusion, such as coloring. Its benefits include:

Increased durability

Lower maintenance costs

Aesthetically pleasing appearance

No peeling

No flaking

Buffing is a mechanical finishing operation in which a buffing compound containing aluminum oxide is applied to the surface of an aluminum extrusion by rotating fabric wheels for the purpose of removing minor imperfections and developing a lustrous finish.

Sanding develops a desirable scratch finish using either flat or spiral sanders and is strictly done for cosmetic purposes. The amount of metal removed is dependent upon the grit finish used.