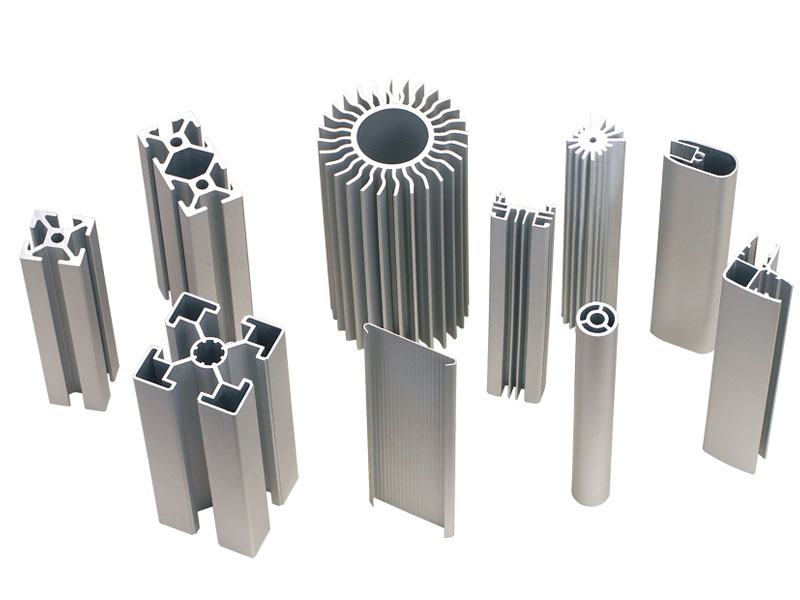

Features of Aluminium Window Profiles

| Alloy | Standard | Surface Treatment | Further Process | Certificate |

| 6005 T5/T6, 6060 T5/T6, 6061 T4/T6, 6063 T5/T6, 6463 T5/T6, 6082 T5/T6, etc. | GB 5237-2008, JISH, AAMA, GB, BS, En | Mill finish, Powder Coating, Anodizing, Wooden grain, Electrophoresis, PVDF Painting, Sanding blasting, Polishing, etc. | Drilling, Bending, Welding, Precise cutting, Punching, Fabrication of finished products, etc. | CE, DNV, TUV, ISO9001

|

Specifications of Aluminium Casement Window & Door

| System Reference |

Description |

|

| 38 Serie Aluminium Casement Window |

38mm Depth Frame |

Download |

| 46 Serie Aluminium Casement Door |

46mm Depth Frame |

Download |

| 51 Serie Aluminium Casement Window |

50mm Depth Frame |

Download |

| 75 Serie Aluminium Casement Door |

75mm Depth Frame |

Download |

| A70 Serie Aluminium Casement Door |

70mm Depth Frame |

Download |

| ZYP50 Serie Aluminium Casement Window |

50mm Depth Frame |

Download |

| ZYP50AG Aluminium Casement Window |

50mm Depth Frame |

Download |

| ZYP55H Aluminium Casement Window |

55mm Depth Frame |

Download |

| ZYP60A Aluminium Casement Window |

60mm Depth Frame |

Download |

| ZYP65A Aluminium Casement Window |

65mm Depth Frame |

Download |

| ZYP150 Aluminium Casement Window |

50mm Depth Frame |

Download |

| ZYP270 Aluminium Casement Window |

70mm Depth Frame |

Download |

| ZYP450 Aluminium Casement Window |

50mm Depth Frame |

Download |

| ZYP460 Aluminium Casement Window |

60mm Depth Frame |

Download |

| ZYPM150 Aluminium Casement Door |

50mm Depth Frame |

Download |

| ZYQ50 Aluminium Casement Window and Door |

50mm Depth Frame |

Download |

| ZYZDM155 Aluminium Folding Door |

57.5mm Depth Frame |

Download |

Specifications of Aluminium Sliding Window & Door

| System Reference |

Description |

|

| 788 Aluminium Silding Window |

75mm Depth Frame |

Download |

| ZY-185 Aluminium Sliding Window |

85mm Depth Frame |

Download |

| ZYT80W Aluminium Sliding Window |

80mm Depth Frame |

Download |

| ZYT90E Aluminium Sliding Window |

90mm Depth Frame |

Download |

| ZYT90J Aluminium Sliding Window |

87mm Depth Frame |

Download |

| ZYT990 Aluminium Sliding Window and Door |

90mm Depth Frame |

Download |

| ZYTM90H Aluminium Sliding Door |

85mm Depth Frame |

Download |

| ZYTM90J Aluminium Sliding Door |

87mm Depth Frame |

Download |

| ZYTM95B Aluminium Sliding Door |

95mm Depth Frame |

Download |

| ZYTM104 Aluminium Sliding Door |

99mm Depth Frame |

Download |

| ZYTM105 Aluminium Sliding Door |

103.4mm Depth Frame |

Download |

| ZYTM190 Aluminium Sliding Door |

90mm Depth Frame |

Download |

| ZYTM285 Aluminium Sliding Door |

85.8mm Depth Frame |

Download |

| ZYTS83 Aluminium Sliding Window |

83mm Depth Frame |

Download |

| ZYZ87 Aluminium Sliding Window |

82.2mm Depth Frame |

Download |

Why Choose Aluminium Windows Profiles

Aluminum window frames are cost-effective, sturdy and durable, while at the same time having functionality and versatility as well as a stylish modern style.

Aluminum window profiles provide highly durable and cost-effective solutions for residential and commercial buildings. They require almost no maintenance, can be used for life, will not rust, and even have a high corrosion resistance limit.

Aluminum window profiles can be provided in standard sizes, and can also be manufactured in customized sizes and styles to meet your specific requirements.

It is also nice to know that your aluminum alloy window frame can be equipped with various types of functional glass. This includes safety protective glass, aesthetic glass, soundproof glass, fireproof glass and bulletproof glass. They can also be double-glazed to provide higher energy efficiency, better acoustics and many other benefits, bringing comfort and security to your house.

The Production Process of Aluminum Window Profile

1. Ingot casting

The process contains the ingredients, melting, casting, homogenization. This is the main process of certain chemical composition and size of the ingot.

2. Extrusion

Extrusion includes an automatic production line composed of ingot heating, extrusion, cooling, straightening, cutting and other processes.

The ingot heating temperature is controlled at 400℃~520℃, too high or too low will directly affect the extrusion.

3. Heat treatment

Through different systems for quenching and aging treatment to obtain the mechanical properties of the profile. Aluminum profile aluminum windows provide materials in RCS state, that is, high temperature heat treatment and rapid cooling are performed after molding and artificial aging.

4. Surface treatment

The most common steps are anodizing, electrophoresis, powder coatings and fluorocarbon coatings so that the surface can have different colors and good appearance. Surface treatment can enhance the aesthetic appearance of the profile and prolong the service life of the aluminum window profile.

English

English 日本語

日本語 한국어

한국어 français

français Español

Español русский

русский português

português العربية

العربية tiếng việt

tiếng việt ไทย

ไทย slovenčina

slovenčina