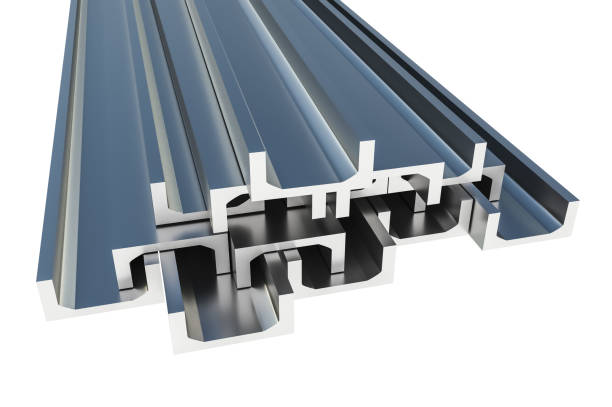

In Otalum, the aluminium U channel also known as u shaped aluminium channel and u shaped aluminium profile, comes in both equal and unequal dimensions, and it can also be cut to a specific size if the existing aluminium U sections do not meet your requirements.

As a professional aluminium profile company in China, Otalum mainly produces our U-shaped aluminium channels/profiles according to the standard GB5237.1-2017. In terms of the raw materials, Otalum's extruded aluminium U profile channel mainly uses alloys including 6005, 6060, 6061, 6063, 6082, etc.

Otalum is a professional supplier of u aluminium channel profiles. We offer different types of U aluminium extrusion channel profiles as you can see below. If you want to know more details about Otalum U shaped aluminium extrusion channel, please feel free to contact us.

Precise cutting to length and processing services are also available with the fastest lead time in the current industry.

Aluminum U channels also known as u shaped aluminium channels and u shaped aluminium profiles, offer a large range of applications across many industries. The most common uses include framing, tracks, slides, protective edges, railings, rails, rims, and decoration, to name just a few.

U-shaped aluminum channels, also known as U-channel or U-sections, have a wide range of applications due to their versatility and strength. Here are some common uses for U-shaped aluminum channels:

Construction: U-shaped aluminum channels are often used in the construction industry for structural support, framing, and reinforcement of walls, ceilings, and floors.

Electrical: U-shaped aluminium extrusion channel profiles can be used to house electrical wiring or as conduits for electrical cables.

Industrial: U-shaped aluminum channels can be used for the construction of machinery, equipment, and conveyor systems.

Automotive: U-shaped aluminum channels can be used in the manufacturing of automobile frames, bumpers, and other parts.

Marine: U-shaped aluminum channels are often used in the marine industry for boat building and repair.

Aerospace: U-shaped aluminium channel can be used in the aerospace industry for the construction of aircraft frames, wings, and other components.

Overall, U section aluminium channels are used in various industries and applications where strength, durability, and versatility are required.

1. High electrical and thermal conductivity.

By weight, aluminum is twice as conductive as copper, making it the most commonly used material for large-capacity overhead power lines. Light intensity. Aluminum has a high strength-to-weight ratio, making it the best solution to the challenge of lightweight load-bearing.

2. Heat transfer and shielding.

Where weight and stiffness are the main considerations (aerospace applications), aluminum has better heat transfer and shielding performance than copper shielding.

3. Corrosion and rust resistance.

When exposed to the air, aluminum will form an oxide coating to prevent rust and corrosion. If necessary, the coating can be enhanced by anodizing.

4. Non-magnetic

In applications where the magnetic properties of the material cause problems, the non-magnetic properties of aluminum are particularly valuable.

5. There is no spark

Because it does not generate sparks, aluminum is usually the best solution for highly flammable or explosive applications.

6. 100% recyclable

In the recycling process, aluminum is equivalent to the original material and is not degraded. In addition, aluminum recycling only requires 5% of the energy input required to process the original material.

7. Low toxicity and high reflectivity are other characteristics that make aluminum channels the material of choice. Users with apps that benefit from these features will look for the best solution for aluminum channels.

Aluminum channels are also commonly called C-channels or U-channels-depending on how you hold it, they are usually used for general manufacturing, light construction works, decoration, shop decoration, vehicle manufacturing, and shipbuilding.

U aluminium extrusion channel profiles are easy to manufacture because aluminum can be easily cut with a power tool or hacksaw; you can also drill and process it very easily.

The correct tools and equipment can be used for welding. Although it requires more skills than welding mild steel, why not try it-we provide a full range of aluminum electrodes, machines and consumables.

Pure aluminum is relatively soft, but it is usually alloyed with other metals to improve its mechanical properties. It is a durable, light-weight metal, non-ferromagnetic and difficult to ignite, has good corrosion resistance and excellent strength-to-weight ratio.

The U shaped aluminium extrusion channel has a rolling finish, which is the finish and surface state of aluminum immediately after extrusion. Different batches, manufacturers, and even products produced in the same batch have very different finishes and surface visual characteristics.