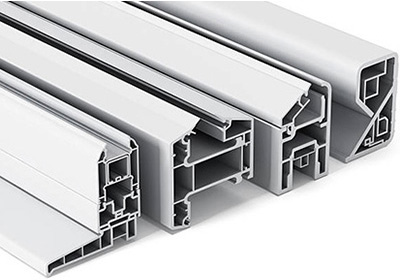

Otalum produces a large number of architectural aluminium profiles also known as aluminum construction profiles, used for building and construction areas such as window and doors, curtain walls, fencing and handrail, louvre and walkway covers. These construction aluminium profiles include both standard and thermal-break systems.

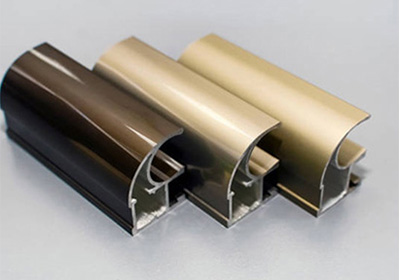

Our architectural aluminum extrusions for architectural systems are available in a variety of finishes which contain mill finish, clear anodized, electrolytic anodizing, powder-coating, PVDF painting and woodgrain finish. We also offer fabrication services of customized architectural aluminum extrusion profiles based on your needs.

All requests are made to orders. When ordering aluminum extrusions construction profiles, please specify your requirements about alloy, temper, length, quantity, surface finish, end-use and any special instructions regarding tolerance, delivery, packing and certification. It couldn't be better if you can share with us your designed drawings.

Due to its structure and cost advantages, aluminum extrusion profiles have become the basic materials as architectural aluminum extrusion profiles. Since aluminum extrusion profile can form complex shapes on continuous long films, it can be used for various building materials. The applications of aluminum extrusion profiles range from railings and railings to building exterior walls and bleaching agents. The strong and lightweight aluminum profile is very suitable for applications such as canopies, because the structure of such applications is not bulky, but must be able to withstand the load. (High stiffness means you need less stiffness, which means more weight can be reduced.) It is also used for suspended ceilings and walls.

The extruded aluminum used in construction is strong, light, durable and highly corrosion resistant. Compared with alternative frame materials such as wood, aluminum profiles do not require regular painting or dyeing to maintain their weather resistance. Aluminum hydroxide can be specified in a variety of finishes and treatment methods, so that it has extremely high thermal efficiency, ideal performance, and almost no maintenance in almost any environment.

Features:

Fixing slots on all sides

Unlimited application options

Minimal effort required in construction

Cost optimization

Aluminium extrusion is a metal forming process used to transform lengths of aluminium alloy into objects with a particular cross-section. The aluminium lengths, called billets, are pushed through an extrusion die with a smaller cross-sectional area than the billets themselves. The billets take on the shape of the cross-section on the die, so they can be used in various applications. The aluminium extrusion process is a relatively quick, simple and cost-effective one, and aluminium is particularly suited to this kind of form.

It depends on the nature of your project. Wherever possible, we use 6000 series aluminium extrusion alloys, as they are widely available and suited for commercial use. Of the available aluminium extrusion grades, we primarily use:

6063

6061

6005

6082

There are other available aluminium extrusion grades, however, there would rarely be a case in which we would need to use these. If you are unsure of whether the available aluminium extrusion grades are suited to your intended application, or would like to know which grade we would recommend, please feel free to contact us.

Aluminium is cost-effective, lightweight and easy to work with. However, it's also very good at conducting heat, which isn't ideal when it's used for things like windows and doors. It offers poor insulation in winter and little protection from heat in summer.

Thermal break extruded aluminium profiles solve this problem. A thermal break profile is effectively an aluminium sandwich and contains non-conductive material that acts as a thermal 'break' or barrier. These profiles can conduct up to 1,000 times less heat than aluminium alone.

Solid refers to a shape with no cavities at all, like flat bars or rods. Semi-hollow is a shape that is partially enclosed but always keep a gap open, even very small. Hollow shapes contain one or more totally closed areas like a tube.

How much aluminium extrusion costs per kilo is governed by the London Metal Exchange (LME) or another local aluminium price, taking into account the global market and fluctuations in supply and demand. What this means is that the cost per kilo of aluminium extrusion is never the same. In addition, aluminium is traded in US dollars, which means that we have to take the exchange rate into account.

In order to protect our customers from price fluctuations, we offer prices that are fixed for 7 to 15 days after a quote is first produced. So if the cost per kg of aluminium extrusion increases a day after we’ve quoted you, we'll absorb that cost.

If you wish to secure a fixed cost per kg for a period of up to 12 months, we can arrange to forward purchase metal as a means of securing this price. Having a fixed aluminium extrusion cost per kg for a year can give you a valuable period of price security that proves particularly helpful in the early days of your business, or in lean times. It also makes good business sense!

Aluminum alloy is soft and usually alloyed with copper, zinc, magnesium, silicon, manganese and lithium to increase strength. When aluminum alloy is exposed to air, an anti-oxidant coating will be formed instantly to protect products. Aluminum alloy is one of the lightest metals. The application of products ranges from precision technology to daily commodities.